Mercedes-Benz EQS - Virtual Production

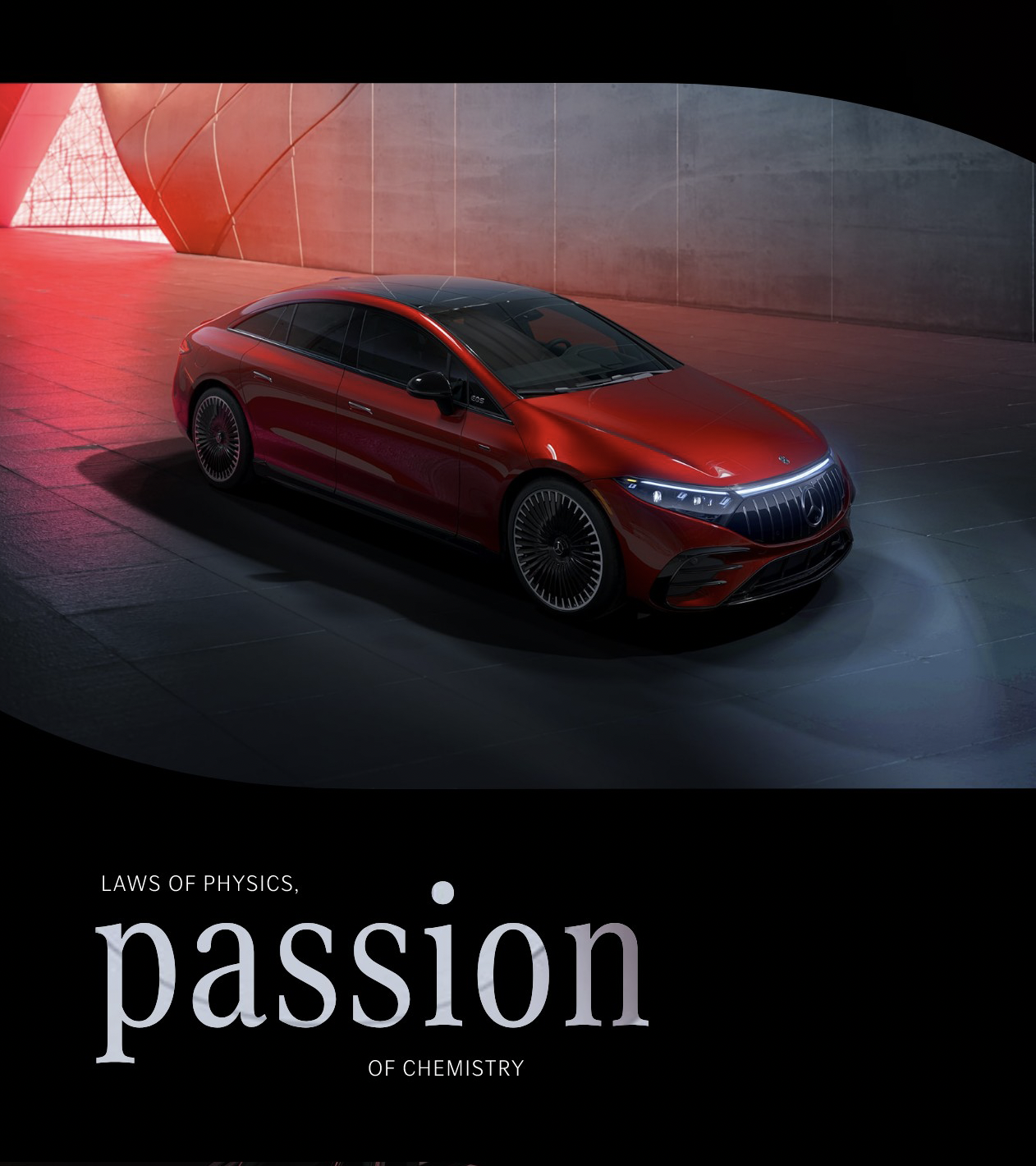

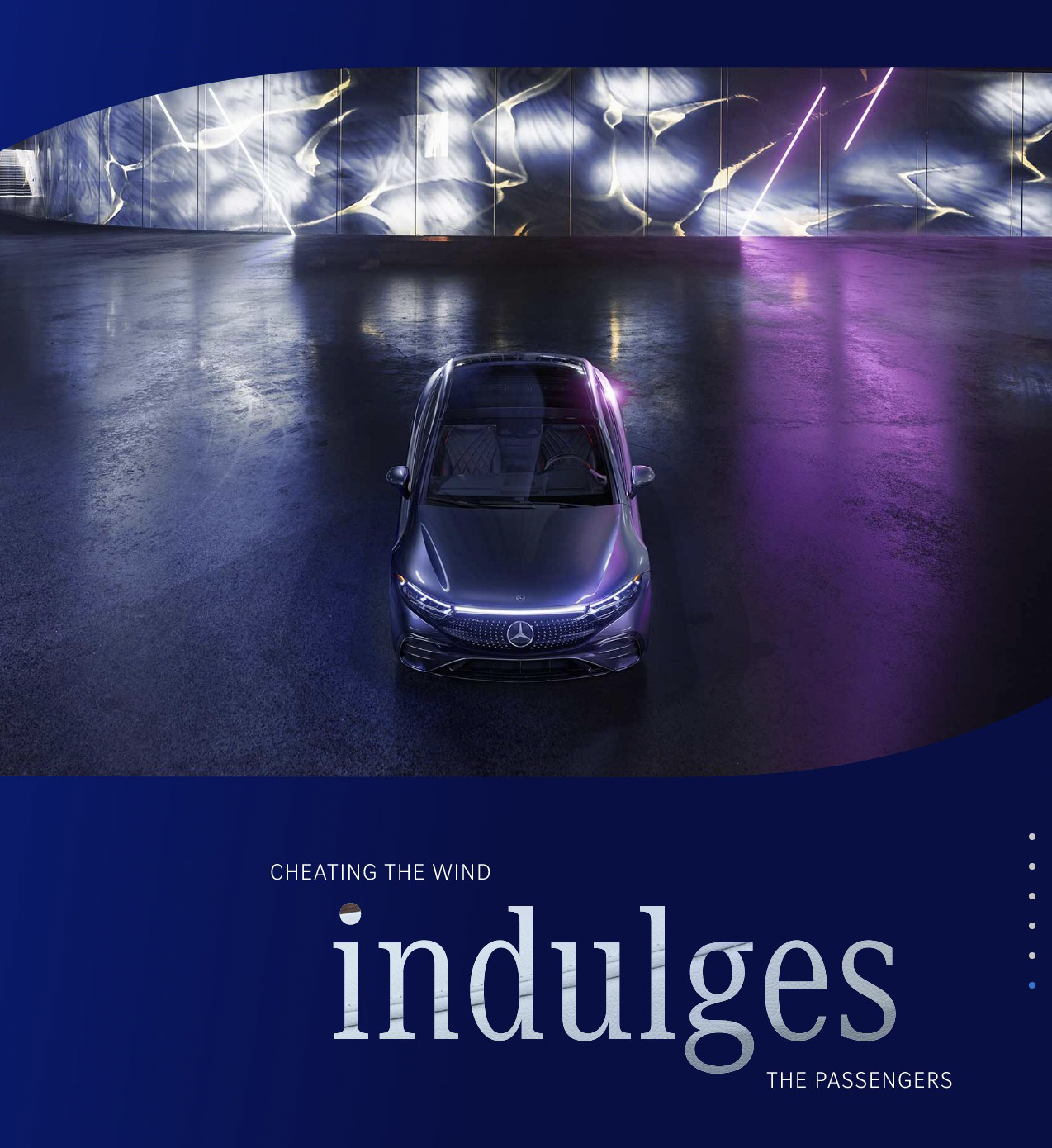

Virtual production using backplates and HDR domes offers a sustainable way for companies to create stunning visuals. The marketing campaign for the new Mercedes-Benz EQS showcases the amazing results that can be achieved with this technology.

As the world continues to shift towards more sustainable and environmentally-friendly practices, it's becoming increasingly important for companies to adopt these practices in all areas of their business, including marketing. One way that companies can do this is by using virtual production techniques for their marketing visuals, as seen in the recent marketing campaign for the new full electric Mercedes-Benz EQS.

Virtual production is a cutting-edge technology that allows companies to create stunning visuals without the need for traditional photo shoots. This not only saves resources but also has a much lower carbon footprint than conventional photo productions, making it a more sustainable option.

One key component of virtual production is the use of backplates and HDR domes. Backplates are high-resolution images of a specific location or environment that are used as the background for a key visual. By using backplates, companies can create images that look incredibly realistic, even though they were created entirely in a virtual environment.

HDR domes, on the other hand, are 360-degree images that capture the entire environment, including the sky and surrounding landscapes. These images are

then used to provide the lighting for the visuals, allowing for incredibly realistic and lifelike lighting and reflections.

The marketing visuals for the new full electric Mercedes-Benz EQS are a prime example of the amazing results that can be achieved through virtual production. The use of backplates and HDR domes allowed the team to create images that truly capture the innovative and emission-free nature of the EQS.

Incorporating sustainable practices into marketing strategy is not only promoting the product and a greener future but is also setting an example for other companies to follow.

We are proud to be a part of this project and excited to see the impact that the EQS will have on the automotive industry. Every small action we take toward sustainability can make a big difference in the long run.